Our material is Biodegradable which aids reinforcement and toughness in friction linings/shoes/pads. Its fiber-like structure gives improved friction stability while reducing cracking. Blending into formulations can not only increase strength of friction materials, but also improve shear strength and impact strength. Our material is good at stabilizing friction coefficient. Recommendation dosage: 8% to 15%, Maximum 20%. The actual dosage is subject to customers formulation design.

The hardness of mineral fiber, steel fibers, ceramic fibers are usually higher with shot unavoidably, commonly these fibers lead to noise. Also our material do not produce black ashes, but it can reduce phenomenon of falling ash when braking.

For Brake Pads

For Brake Pads

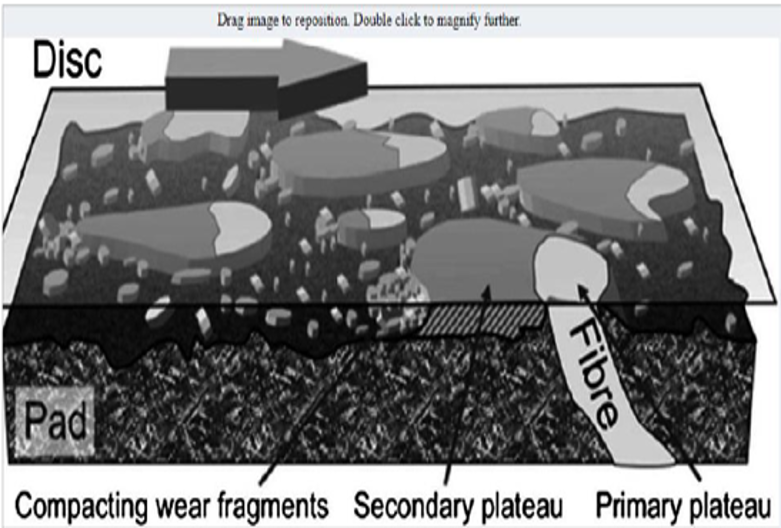

Picture is the illustration of the contact situation between the pad and disc. A transparent disc is moving from left to right. Some of the wear particles pile up against the contact plateaus and create secondary plateaus. A flow of wear particles in the gap between the pad and disc wear the lowlands of the pad through three-body abrasion .

| Chemical Composition | Appearance | Micro-morphology | Whiteness (%) | Loose Density (g/cm³) | Moisture Content (%) | pH Value | Mohs Hardness | Particle Size D50 | Particle Size D90 |

|---|---|---|---|---|---|---|---|---|---|

| Ca5Si6O16(OH)2·4H2O | White Powder | Porous Spherical | ≥ 90 | 0.1 – 0.2 | ≤ 3 | 9 – 12 | 6 – 7 | 5 – 20 μm | 60 – 120 μm |

It can be used in many fields such as the friction material industry, polymer compounding industry, high-end building materials, etc.

Be stored in a cool, dry and ventilated place.

| Chemical Composition | Appearance | Particle Shape | Purity (%) | Length (µm) | Diameter (µm) | L/D Ratio | Whiteness (%) | Gravity (g/cm³) | Loose Density (g/cm³) | Moisture Content (%) | Heat Resistant (℃) | Melting Point (℃) | pH Value | Mohs Hardness |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CaSO4 | White Powder | Rod-like Shape Fiber | ≥95 | 10-200µm (90%) | 1-20µm (90%) | 10-80 (90%) | > 90 | 2.69 | 0.3-0.4 | < 1.5 | 1000 | 1450 | 6.5-7.5 | 3 |

12.5KG/Bag (Inner Plastic Bag plus Kraft Paper Bag Outside)

60 bags, 750 kg totally with wrapping onto one composite pallet under ISPM-15 regulation.

| Chemical Composition | Appearance | Particle Shape | Purity (%) | Length (µm) | Diameter (µm) | L/D Ratio | Whiteness (%) | Gravity (g/cm³) | Loose Density (g/cm³) | Moisture Content (%) | Heat Resistance (℃) | Melting Point (℃) | pH Value | Mohs Hardness |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CaSO4 | White Powder | Rod-like Shape Fiber | ≥ 95 | 10-100 µm (90%) | 1-10 µm (90%) | 10-80 (90%) | > 90 | 2.69 | 0.2-0.35 | < 1.5 | 1000 | 1450 | 7 ± 0.5 | 3 |

12.5KGS/Bag (Inner Plastic Bag plus Kraft Paper Bag Outside)

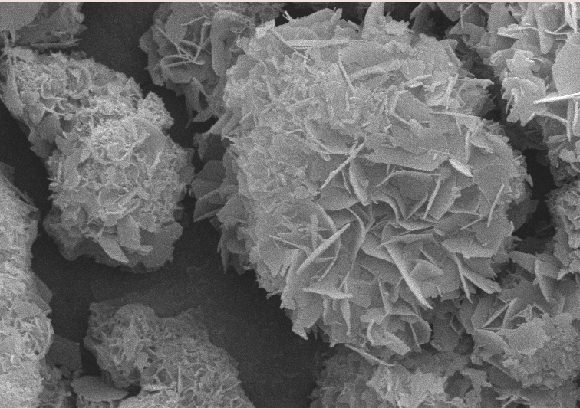

| Chemical Formula | Appearance | Microscopic Appearance | Diameter (μm) | Gravity (g/cm³) | Loose Density (g/cm³) | Moisture Content (%) | pH Value | Mohs Hardness | Heat Resistant (℃) | Melting Point (℃) |

|---|---|---|---|---|---|---|---|---|---|---|

| K2MgTi4O10 | White Powder | Flaky, Oblate Crystal | 5-20 μm | 3-3.3 | 1-1.3 | ≤ 1.5 | 9-11 | 4 | 1200 | > 1300 |

25KG/Bag (Inner Plastic Bag plus Kraft Paper Bag Outside)

36 bags, 900 kg totally with wrapping onto one composite pallet under ISPM-15

regulation.

(1) : Used as friction control agent : Widely used in the production of automobile ceramic brake pads, train brake shoes and clutch friction plates, etc.

(2) : Used as a reinforcing agent for engineering plastics : Used to reinforce plastic composite materials and improve the mechanical properties . It is suitable for

producing various high-strength, heat-resistant and wear-resistant precision parts.

| Chemical Composition | Appearance | Micro Appearance | Components (Aluminum-titanium oxide) | Loose Density (g/cm³) | Moisture (%) | Diameter (μm/D90) | pH | Hardness |

|---|---|---|---|---|---|---|---|---|

| NP-F02-YG | Grey Powder | Granule | ≥90% | 0.6–0.8 | ≤0.5 | 600 | 10–12.5 | 5 |

It is widely used as a friction enhancing material in automobile brake pads, train brake shoes, Clutch and other friction materials.

The aluminum titanium powder has obvious effect in increasing friction in low, medium and high temperature environments.

It is recommended to add the proportion of 3-8%, which can reduce the adding ration of resin and other high price materials to lower the cost.

Copyright © 2025 Anourav Innovative Materials Pvt Ltd, All rights reserved. Developed & designed by Buzzing Brands