Dedicated to resin bonded cutting wheel industry

| Chemical Composition | Appearance | Particle Shape | Purity (%) | Length (μm) | Diameter (μm) | L/D Ratio | Whiteness (%) | Gravity (g/cm³) | Loose Density (g/cm³) | Moisture Content (%) | Heat Resistant (℃) | Melting Point (℃) | pH Value | Mohs Hardness |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CaSO4 | White Powder | Rod-like Shape Fiber | ≥95 | 10–100μm (90%) | 1–10μm (90%) | 5–50 (90%) | > 90 | 2.69 | 0.3–0.5 | < 1.5 | 1000 | 1450 | 6.5–7.5 | 3 |

25KG/Bag (Inner Plastic Bag plus Kraft Paper Bag Outside)

36 bags, 900 kg totally with wrapping onto one composite pallet under ISPM-15

regulation.

The suggested dosage is about 3-8%, below is the formulation that we used in 107×1 metal cutting wheel. But this is just recommendation formulation that based on our domestic market. Just for your reference. You can aslo adjust your recipe based on our suggestion.

Take 100g abrasive grains for example, First we should weight 100g Abrasive grains , and then 30g binding agent + 12g potassium cryolit + our calcium sulphate fiber 6g + others……

46# White plated Corundum : 50% White Corundum : 50% Binding agent : 30% ( with high-viscosity resin liquid ) Potassium Cryolit : 12% Calcium Sulphate fiber : 6% The pigment can be kept the original proporation.

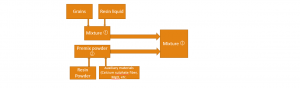

Technics:Upper/Lower pots mixing

Technics process:

Mixture ①: Resin liquid+ grains mixing in Upper pot as normal minutes Premix powder ②:In lower pot, premix auxiliaries (calcium sulphate fiber, Mgo, etc)+ grains for 2-3 minutes; Mixture ③: Mixture ①pouring over to Premix powder ② and mix over 5 minutes or adjust minute as per actual situation.

Copyright © 2025 Anourav Innovative Materials Pvt Ltd, All rights reserved. Developed & designed by Buzzing Brands